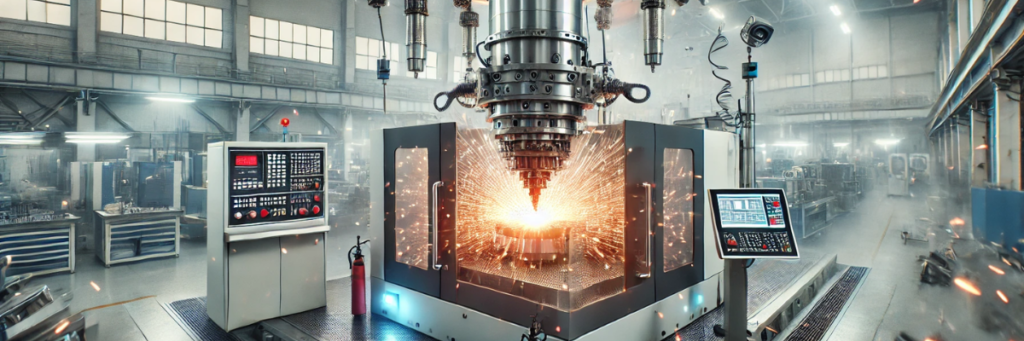

Electrical Discharge Machines (EDM) play a vital role in precision manufacturing across industries like aerospace, automotive, and medical equipment production. These machines use high-energy electrical discharges (sparks) to cut and shape metal, generating intense heat and increasing the risk of fire. The presence of flammable dielectric fluids and complex electrical systems makes fire safety a critical concern.To minimize the risk of catastrophic fires, installing an Pre Engineered Fire Suppression Systems is essential to protect both machinery and personnel. In this guide, we’ll explore the fire hazards associated with EDM machines, the best fire suppression systems, and key fire prevention strategies to ensure a safe and efficient manufacturing environment.

In this blog, we will explore the fire risks associated with EDM machines and the best fire suppression systems to ensure a safe and efficient working environment.

Why Fire Suppression is Essential for EDM Machines

EDM machines are unique in their operation, relying on electrical discharges (sparks) to remove material from the workpiece. While highly effective for precision cutting, the process generates heat, which, when combined with flammable dielectric fluids, presents a high risk of fire.

Key Fire Risks in EDM Machines:

- Flammable Dielectric Fluids: EDM machines often use dielectric fluids, such as oil-based coolants, to submerge the workpiece and improve the cutting process. These fluids can ignite if exposed to the sparks generated by the machine.

- High-Temperature Sparks: The electrical discharges produced by the EDM process can reach extremely high temperatures, which can ignite flammable materials or cause nearby substances to overheat and catch fire.

- Electrical Malfunctions: As with any machine that uses electricity, electrical faults like short circuits, overloads, or equipment malfunctions can create sparks or heat that lead to fires.

- Continuous Operation: EDM machines often operate for long periods, which increases the risk of overheating, especially in high-intensity production environments.

Without adequate fire suppression, even a small fire can cause significant damage to equipment, disrupt operations, and put workers at risk.

Types of Fire Suppression Systems for EDM Machines

Several fire suppression systems are suitable for EDM machines, each designed to detect and extinguish fires effectively before they spread. The choice of system depends on the specific fire risks in your facility and the type of EDM machine in use. Here are the most effective fire suppression systems for EDM machines:

1. Clean Agent Fire Suppression Systems

Clean agent fire suppression systems are one of the most popular choices for protecting EDM machines. These systems use gas-based fire suppression agents that extinguish fires without leaving any residue, making them ideal for environments with sensitive machinery.

- How It Works: Clean agents, such as FM-200 or NOVEC 1230, absorb heat and interrupt the chemical reactions necessary for combustion. These gases are non-conductive and non-toxic, making them safe to use around sensitive electronic components in EDM machines.

- Benefits: Clean agent systems are fast-acting, extinguishing fires in seconds without damaging equipment or requiring cleanup. They are effective in suppressing fires involving flammable dielectric fluids and electrical components.

- Best Use Cases: Clean agent systems are ideal for EDM machines in precision manufacturing environments where avoiding equipment damage and minimizing downtime are critical.

2. CO2 Fire Suppression Systems

Carbon dioxide (CO2) fire suppression systems are highly effective in environments where flammable liquids and electrical equipment are present. CO2 is a colorless, odorless gas that works by displacing oxygen, effectively suffocating the fire.

- How It Works: CO2 suppresses fires by reducing the oxygen level in the air to below the point where combustion can occur. It is particularly useful for fighting fires that involve flammable liquids, such as the dielectric fluids used in EDM machines.

- Benefits: CO2 systems leave no residue and do not require cleanup, making them an excellent choice for protecting EDM machines from fire damage. Additionally, CO2 is non-conductive, so it is safe to use around electrical components.

- Best Use Cases: CO2 systems are ideal for EDM machines that use flammable fluids, particularly in high-risk areas where flammable materials and sparks are present.

3. Automatic Dry Chemical Fire Suppression Systems

Dry chemical fire suppression systems use powdered chemicals to extinguish fires. These systems are commonly used in environments where flammable liquids and electrical fires are a risk.

- How It Works: Dry chemical systems release a fine powder that interrupts the chemical reactions necessary for combustion. The powder effectively blankets the fire, smothering it and preventing the spread of flames.

- Benefits: Dry chemical systems are highly effective at suppressing fires caused by flammable liquids or electrical malfunctions. However, they do leave a residue, which requires cleanup and may not be ideal for sensitive equipment.

- Best Use Cases: Dry chemical systems are well-suited for industrial environments with multiple fire hazards, including flammable liquids and electrical fires.

4. Water Mist Fire Suppression Systems

Water mist fire suppression systems use a fine mist of water droplets to cool and suppress fires. These systems are particularly effective at cooling hot surfaces and preventing the spread of flames.

- How It Works: Water mist systems release a fine mist of water that absorbs heat and reduces the temperature of the fire. The mist is fine enough to cool the fire without damaging sensitive machinery or causing electrical short circuits.

- Benefits: Water mist systems are highly effective at cooling EDM machines and preventing overheating, while also being safe for use around electrical components. The fine mist minimizes water damage, unlike traditional sprinkler systems.

- Best Use Cases: Water mist systems are ideal for environments where overheating is a major fire risk. They are suitable for EDM machines that require temperature control and fire suppression without damaging equipment.

5. Foam Fire Suppression Systems

Foam fire suppression systems are designed to fight fires involving flammable liquids, such as dielectric fluids used in EDM machines. These systems blanket the fire with foam, cutting off its oxygen supply and suppressing flames.

- How It Works: Foam systems release a layer of foam over the fire, smothering the flames and preventing oxygen from reaching the fuel. The foam also helps prevent re-ignition by cooling the fire and covering any remaining flammable liquid.

- Benefits: Foam systems are highly effective for fires involving flammable liquids. The foam forms a protective barrier that prevents the spread of fire and contains the flammable fluids.

- Best Use Cases: Foam fire suppression systems are ideal for EDM machines that use flammable dielectric fluids, especially in environments where fluid spills or leaks are common.

Fire Prevention Tips for EDM Machines

In addition to installing an effective fire suppression system, there are several steps you can take to minimize fire risks when operating EDM machines.

1.Regular Maintenance & Inspections:

- Check electrical connections, motors, and wiring for wear and tear.

- Monitor dielectric fluid levels and inspect for leaks or spills.

- Replace worn-out components to prevent overheating.

2. Control the Use of Dielectric Fluids

The dielectric fluids used in EDM machines are flammable, so it’s important to handle them with care.

- Use Non-Flammable Fluids: Whenever possible, use non-flammable or fire-resistant dielectric fluids to reduce the risk of fire.

- Proper Storage: Store flammable fluids in approved containers and keep them away from heat sources and electrical components.

3. Ensure Proper Ventilation

Good ventilation is essential to dissipate heat generated by EDM machines and to prevent the build-up of flammable vapors.

- Install Exhaust Systems: Ensure that your EDM room has proper exhaust systems to remove heat and vapors from the environment.

- Monitor Airflow: Regularly check the airflow around the EDM machine to ensure that heat is dissipating properly and that there is no accumulation of flammable vapors.

4. Employee Training

Proper training of operators is essential for fire prevention.

- Train on Fire Safety Procedures: Ensure that all operators are trained in fire safety protocols, including how to respond to a fire, shut down equipment, and use fire suppression systems.

- Safe Operation Practices: Train employees on the proper operation of EDM machines, including safe handling of dielectric fluids and the importance of regular machine maintenance.