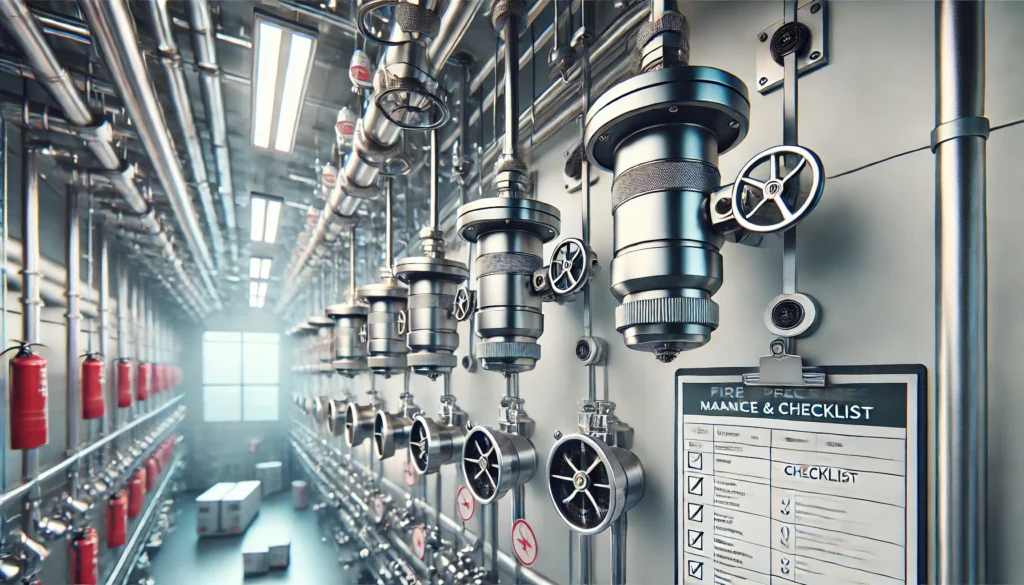

Regular maintenance of fire suppression nozzles is essential for ensuring the effectiveness, reliability, and compliance of the system with safety regulations. A structured inspection, cleaning, and maintenance approach minimizes risks and enhances system performance.

1. Routine Inspection Schedule

| Frequency | Inspection Task |

|---|---|

| Weekly | Perform a visual inspection for physical damage, clogging, or misalignment. |

| Monthly | Check nozzle positioning and ensure there are no obstructions. |

| Quarterly | Clean nozzles and check water pressure to maintain proper spray patterns. |

| Annually | Conduct full system testing, including nozzle flow test and alignment verification. |

| Every 5 Years | Perform an internal inspection of nozzles, pipes, and spray heads for corrosion or wear. |

2. Nozzle Maintenance Procedure

A. Visual Inspection

- Check for physical damage, corrosion, or clogging.

- Ensure nozzles are properly aligned with designated coverage areas.

- Inspect seals and gaskets for leaks or deterioration.

B. Cleaning Nozzles

- Remove dust, dirt, or residue using a soft brush or compressed air.

- Flush clogged nozzles with clean water or manufacturer-approved solvent.

- Avoid abrasive tools that could damage the nozzle orifice.

C. Testing Spray Patterns

- Conduct a water flow test to verify the correct spray pattern.

- Use a pressure gauge to ensure the nozzle receives adequate water pressure.

- If water distribution is uneven, adjust or replace the nozzle.

D. Checking Nozzle Seals and Connections

- Inspect threaded connections and gaskets for leaks.

- Tighten loose fittings carefully to prevent cracks.

- Replace worn-out seals to avoid leakage.

E. Corrosion Prevention

- Apply anti-corrosion coating for metallic nozzles, if specified by the manufacturer.

- Ensure pipes and fittings are free from rust or sediment that could clog nozzles.

- In coastal or humid environments, inspect for salt buildup and oxidation.

3. Special Maintenance Tips

- Use only manufacturer-approved cleaning agents to avoid nozzle damage.

- Disable the fire suppression system before conducting any maintenance.

- Document all inspections and maintenance activities for compliance with NFPA 25 and local regulations.

- Replace defective nozzles immediately to ensure system integrity.

- Train personnel on proper handling, maintenance, and emergency troubleshooting.

4. Fire Suppression Nozzle Maintenance Checklist

| Inspection Task | Frequency |

| Check for physical damage or corrosion on nozzles. | Weekly |

| Ensure nozzles are properly aligned with coverage area. | Weekly |

| Inspect for obstructions (dust, dirt, residue, grease). | Weekly |

| Flush clogged nozzles with clean water or approved solvent. | Monthly |

| Perform a water flow test to verify spray pattern. | Quarterly |

| Check water pressure at the nozzle using a pressure gauge. | Quarterly |

| Inspect seals and gaskets for wear or leaks. | Quarterly |

| Verify proper tightening of nozzle fittings. | Quarterly |

| Apply anti-corrosion coating (if applicable). | Annually |

| Ensure pipes and fittings are rust-free. | Annually |

| Check for salt buildup in humid/coastal areas. | Annually |

| Disable fire suppression system before performing maintenance. | Before Maintenance |

| Replace any defective nozzles immediately. | As Needed |

| Record findings and actions in the maintenance log. | Every Inspection |

| Ensure trained personnel handle nozzle maintenance. | Ongoing |