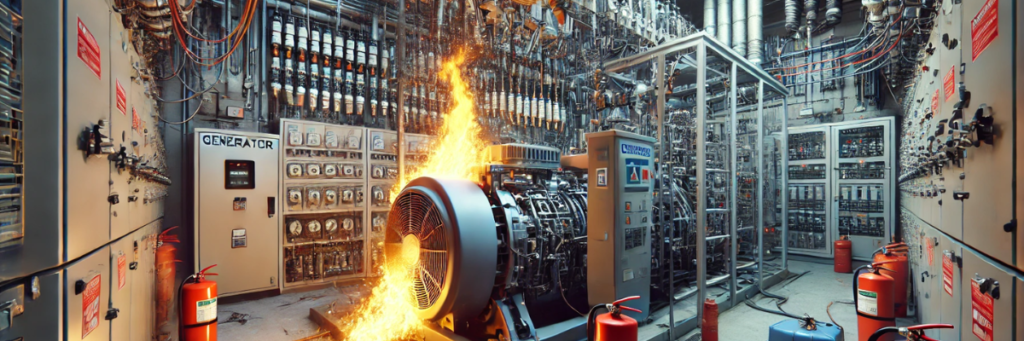

Generator rooms are vital to many facilities, serving as backup power sources during outages and ensuring that critical operations can continue without interruption. However, the combination of fuel, electrical components, and mechanical equipment in generator rooms creates significant fire risks. If a fire breaks out in a generator room, it can lead to costly damage, operational downtime, and potential safety hazards for personnel. Understanding the typical causes of fire in generator rooms and knowing how to prevent them is crucial for maintaining a safe and efficient operation.

In this blog, we will explore the common causes of fires in generator rooms and provide practical strategies to protect these spaces from fire risks.

Common Causes of Fires in Generator Rooms

1. Fuel Leaks and Combustible Liquids

Generators typically run on fuel, such as diesel or gasoline, which are highly flammable. Fuel leaks or improper handling of combustible liquids are among the most common causes of fires in generator rooms.

- Fuel Spills: Spills during fuel transfer or leaks from fuel tanks, lines, or fittings can lead to the accumulation of flammable vapors, which may ignite if they come into contact with a heat source or spark.

- Improper Storage: Storing fuel in unapproved containers or in proximity to heat sources increases the risk of fire in generator rooms.

2. Electrical Malfunctions

Generator rooms house complex electrical systems that can malfunction and cause fires if not properly maintained.

- Short Circuits: Faulty wiring or damaged electrical connections can cause short circuits, resulting in sparks or overheating that may ignite nearby combustible materials or vapors.

- Overloaded Circuits: Generators and their associated electrical systems require significant power loads, and overloaded circuits can overheat, increasing the likelihood of electrical fires.

- Faulty Electrical Components: Malfunctioning components such as transfer switches, control panels, or motors can generate sparks or heat, which can lead to fires in generator rooms.

3. Overheating of Generators

Generators generate a substantial amount of heat during operation, and overheating is a common cause of fire in generator rooms.

- Blocked Ventilation: Insufficient ventilation or obstructed airflow can cause the generator to overheat, leading to the ignition of nearby combustible materials.

- Continuous Operation: Operating the generator for extended periods without adequate cooling or breaks can cause parts to overheat and become a fire hazard.

- Failure of Cooling Systems: If the generator’s cooling system fails or becomes clogged, heat will build up, increasing the risk of fire.

4. Oil Leaks

Generators require lubricating oil for smooth operation. Oil leaks are a fire hazard because oil can ignite if it comes into contact with hot surfaces or sparks.

- Leaking Gaskets or Seals: Worn-out gaskets, seals, or fittings can lead to oil leaks, which can ignite when exposed to hot components of the generator.

- Poor Maintenance: Failing to maintain or inspect oil levels and seals regularly can lead to undetected leaks, increasing the risk of fire.

5. Accumulation of Flammable Debris

Debris such as dust, dirt, and paper can accumulate in generator rooms, particularly around exhaust systems and electrical components. This debris can become a fire hazard if exposed to heat or sparks.

- Debris Near Exhaust Pipes: Hot exhaust pipes can ignite any flammable debris that accumulates nearby.

- Dust Build-Up on Electrical Components: Dust accumulation on electrical panels or circuits can ignite if it comes into contact with sparks or heat.

6. Improper Use or Operation of Equipment

Human error is a common cause of fires in generator rooms. Improper use or mishandling of the generator or its fuel can lead to dangerous situations.

- Improper Fueling Procedures: Refueling a hot generator or using inappropriate fuel can lead to fires.

- Neglecting Safety Protocols: Failing to follow safety protocols when operating or maintaining generators, such as allowing flammable materials to come into contact with the generator, can result in fire hazards.

Ways to Protect Generator Rooms from Fire Hazards

1. Implement Proper Fuel Management

Since fuel is one of the primary fire hazards in generator rooms, careful management and storage of fuel are critical for fire prevention.

- Use Approved Storage Containers: Store fuel in approved, fire-resistant containers and keep them in well-ventilated areas away from heat sources or electrical equipment.

- Check for Leaks Regularly: Inspect fuel lines, tanks, and fittings regularly to detect and repair leaks before they become a fire hazard.

- Follow Safe Refueling Procedures: Ensure that generators are turned off and allowed to cool down before refueling. Never refuel a generator while it is running.

2. Maintain and Inspect Electrical Systems

Proper maintenance and regular inspections of the electrical systems in generator rooms can prevent fires caused by short circuits, overloaded circuits, and faulty components.

- Scheduled Electrical Inspections: Have a qualified electrician regularly inspect all electrical wiring, connections, and components to detect any faults or potential fire hazards. Replace worn-out or damaged wiring immediately.

- Install Circuit Protection Devices: Use circuit breakers and fuses to protect electrical systems from overloading. These devices can shut off the power in the event of an electrical fault, reducing the risk of fire.

- Ensure Proper Grounding: Properly ground all electrical equipment to prevent static discharge or electrical faults that could lead to fires.

3. Ensure Adequate Ventilation

Proper ventilation is essential for preventing generators from overheating, which is a leading cause of fires.

- Install Exhaust Fans: Use exhaust fans and ventilation systems to remove excess heat from the generator room and keep the temperature within safe operating limits.

- Check Air Vents Regularly: Regularly inspect ventilation systems and air vents to ensure they are free from obstructions. Blocked vents can cause heat to build up and increase the risk of fire.

- Monitor Generator Temperature: Use temperature monitoring systems to track the generator’s operating temperature. Set up automatic shutoff mechanisms to prevent the generator from running if it overheats.

4. Regularly Maintain Generators and Cooling Systems

Proper maintenance is crucial to ensuring that generators and cooling systems function safely and efficiently.

- Scheduled Generator Maintenance: Perform regular maintenance on the generator, including checking oil levels, inspecting gaskets and seals for leaks, and cleaning filters.

- Check Cooling Systems: Ensure that the generator’s cooling system is functioning properly and that there is no build-up of dust or debris that could cause the system to malfunction.

5. Clean the Generator Room Regularly

Keeping the generator room clean and free of debris is critical to preventing fires.

- Remove Flammable Debris: Regularly clean the generator room to remove any accumulated dust, paper, dirt, or other flammable debris that could ignite if exposed to heat or sparks.

- Keep Combustible Materials Away from Hot Surfaces: Ensure that combustible materials are kept away from hot exhaust pipes, electrical panels, and other heat-generating equipment.

6. Install Fire Detection and Suppression Systems

Fire detection and suppression systems are critical for protecting generator rooms from fire damage.

- Smoke and Heat Detectors: Install smoke detectors and heat sensors in the generator room to detect early signs of fire. These systems should be regularly tested to ensure they are functioning properly.

- Automatic Fire Suppression Systems: Equip the generator room with automatic fire suppression systems, such as CO2 or dry chemical systems, that can quickly extinguish fires without damaging electrical equipment.

- Emergency Shutoff Systems: Install emergency shutoff systems that can automatically shut down the generator if it overheats or detects a fire, preventing further damage.

7. Train Employees on Fire Safety Protocols

Employee training is essential to preventing fires caused by human error.

- Fire Safety Training: Provide comprehensive fire safety training to all employees, including safe generator operation, proper fueling procedures, and how to respond in the event of a fire.

- Regular Fire Drills: Conduct regular fire drills to ensure that employees know how to evacuate safely and respond quickly to fire alarms in the generator room.

- Train on Fire Extinguisher Use: Ensure employees are trained in the correct use of fire extinguishers, especially for electrical and fuel-related fires.

Conclusion

Fires in generator rooms can have devastating consequences, but with the right preventive measures, these risks can be significantly reduced. By understanding the typical causes of fire in generator rooms—such as fuel leaks, overheating, electrical malfunctions, and improper equipment use—facilities can take proactive steps to protect their equipment and ensure the safety of their operations.

Implementing proper fuel management, ensuring adequate ventilation, maintaining electrical and cooling systems, and installing fire detection and suppression systems are all critical elements of a comprehensive fire prevention strategy. Additionally, training employees on fire safety protocols ensures that they are prepared to handle any fire risks that may arise in the generator room.

Prioritizing fire safety in generator rooms is not only essential for protecting equipment but also for ensuring the safety of personnel and the continuity of business operations. Organizations should also consider sourcing reliable fire protection system products in India to ensure their safety infrastructure meets both national standards and site-specific requirements.