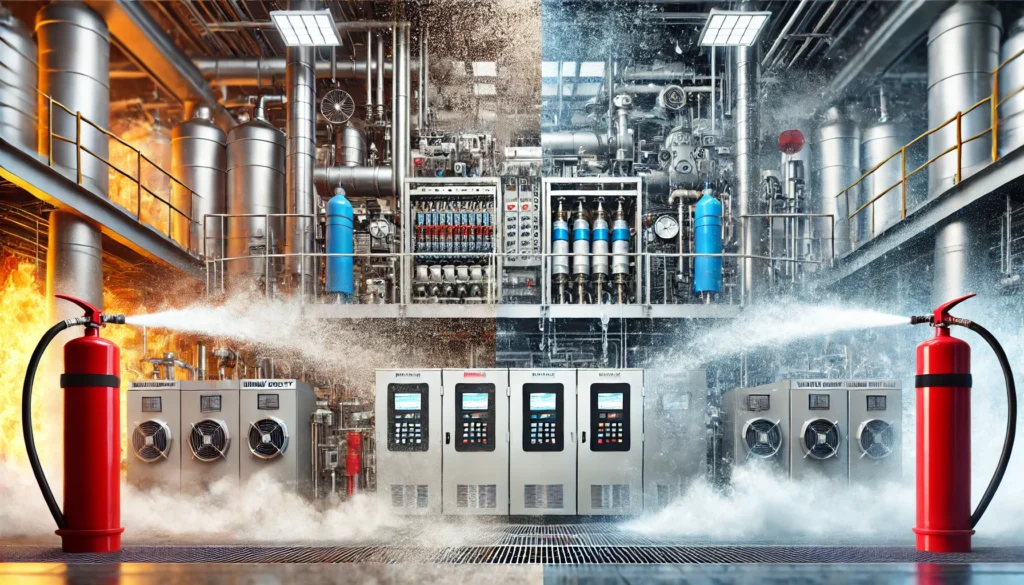

When it comes to fire protection, selecting the right system is crucial for both safety and asset protection. Two commonly used fire suppression systems are Medium Velocity Water Spray (MVWS) and Water Mist Fire Suppression Systems. While both use water as the primary extinguishing agent, they differ significantly in terms of technology, application, and effectiveness. For rapid intervention in urban or industrial settings, especially where vehicle access is limited, innovative solutions like the bike mounted water mist CAF system are proving to be highly effective.

Key Differences Between MVWS and Water Mist Systems

| Feature | Medium Velocity Water Spray (MVWS) | Water Mist Fire Suppression System |

|---|---|---|

| Operating Principle | Uses larger water droplets to cool surfaces and reduce heat radiation. | Uses ultra-fine water mist to suppress fire by rapid cooling, oxygen displacement, and vaporization. |

| Nozzle Type | Medium velocity nozzles that produce controlled water spray. | Specialized high-pressure mist nozzles generating micro-droplets. |

| Droplet Size | 200–400 microns. | 10–200 microns (fine mist). |

| Water Pressure | Operates at moderate pressure (3-7 bar). | Operates at high pressure (35–200 bar) or low pressure (4–15 bar). |

| Fire Suppression Mechanism | Reduces fire intensity by cooling surrounding surfaces and preventing spread. | Suppresses fire through rapid heat absorption and localized oxygen displacement. |

| Water Consumption | High water usage. | Uses up to 90% less water than conventional systems. |

| Applications | Ideal for cooling industrial equipment, protecting storage tanks, and conveyor belts. | Best suited for data centers, hospitals, marine applications, museums, and aircraft hangars. |

| Effectiveness Against Fire Types | Primarily effective for Class A & Class B fires (solid combustibles, flammable liquids). | Works well for Class A, B, and C fires (solid combustibles, flammable liquids, and electrical fires). |

| Water Damage Risk | High due to larger water volume. | Minimal risk, making it ideal for sensitive environments. |

| Installation Cost | Moderate cost, commonly used in industrial applications. | Higher initial cost due to specialized nozzles and high-pressure components. |

Which System is Right for You?

Choose Medium Velocity Water Spray (MVWS) if:

- You need exposure protection for industrial equipment, transformers, or conveyor belts.

- Water consumption is not a major concern.

- The fire risk involves large combustible surfaces where cooling is required.

Choose Water Mist Fire Suppression if:

- You need fire suppression with minimal water damage (e.g., data centers, museums, archives).

- The environment contains electrical equipment or sensitive materials.

- You require a system with higher efficiency in heat absorption and oxygen displacement.

FAQ

1. Which system is better for electrical fires?

Water Mist is preferred because it uses ultra-fine droplets that do not conduct electricity, making it safe for server rooms, control panels, and switchgear rooms.

2. Can MVWS be used in confined spaces?

No, MVWS is designed for open or semi-enclosed areas where large water droplets can cool surfaces effectively. Water Mist is more suitable for confined spaces.

3. How much water does Water Mist save compared to traditional sprinklers?

Water Mist systems use up to 90% less water than conventional sprinkler systems while maintaining high fire suppression effectiveness.